Gravimetric dosing technology fitted for your production

|

||

| KDW“R“ with conveyor channels | KDW 0.1 | KDW“VBR“ with conveyor belts |

continuous dosing weigher |

continuous smallest quantities dosing weigher |

continuous dosing weigher |

continuous dosing

weighers

dosing weighers of series KDW are continuous dosing systems for

granulates and

free flowing bulk of any kind.

outside of our standard equipment we offer

customized solution.

feel free to ask questions

Function: Continuous dosing weigher

The material will be transported out of the hopper (option with level control) by a linear dosing unit in two phases, rough-and fine dosing, into the weighing pan. Then it will be emptied in batches to the conveying channel.The slightest deviation from the set weight will be registrated immediately by the dosing processor DPC3001 and compensated in the same weighing cycle. The conveying channel equalizes the single discharges and guarantees a homogeneous outlet. As conveying systems belts,vibration channels and vibration belts are at your disposal. Especially for bad flowing materials we recommend the use of vibration belts.

conveyor systems: belts, vibration channels, vibration belts and dosing screws

additional modules

conveyor belts (on request)

options: customized adaptations

continuous smallest

quantities dosing weigher kdw 0.1

description:The gravimetric dosing weigher for smallest quantities KDW0.1 is a continuous dosing system. The satisfies high quality requirements. This is based on the isolation of the weighing system (the weighing system is decoupled from the hopper) and the high soluted electronic weighing. The closed housing is made of an aluminum profile frame with removable macrolon windows.Therefore an easy access for the cleaning and maintenance work is guaranteed. All parts which come into contact with the product are manufactured of V2A (material no.1.4301). At the hopper and the material outlet installations for flange mountings are possible to admit the whole system with over-or low pressure.

capacities: 0,05 kg/h – 10 kg/h

dosing control via dosing processor DPC 3001

performance and accuracy specifications are depending on the produc

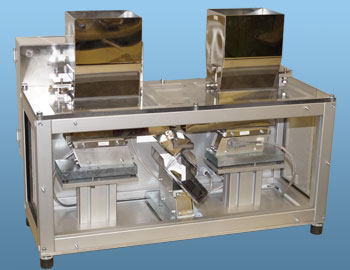

two components smallest quantities dosing weigher KDW 0.1/2K

Plant construction here:closed aluminum profile with makrolon window

2 x hopper with appr. 3 litres volume,

2 x dosing channel with vibrator,

1 x common conveying channel with vibrator,

1 x electronic weighing system with automatic discharge,

1 x weighing pan with appr. 80 ccm volume

all product touching parts in stainless steel V2a (material no: 1.4301).

capacities: 3 kg/h – 10 kg/h

display accuracy: 0.01 g

dosing

performance and accuracy specifications are depending on the product

continuous dosing weigher KDW 0.5 – KDW 5.0

plant construction here:KDW 0.5/VBR (for bad flowing materials):

aluminum profile frame

hopper with appr. 60 litres volume,

dosing belt (instead of channel) with vibrator (VBR),

conveying belt (instead of channel) with vibrator (VBR),

weighing pan with appr. 500 ccm volume

all product touching parts (without belts) in stainless steel V2a

(material no: 1.4301).

capacities: 5 kg/h – 15 kg/h

display accuracy: 0.1 g

dosing control via dosing processor DPC 3001

performance and accuracy specifications are depending on the product

Telefon: 0911 - 96 44 936 Telefax: 0911 - 96 44 938 E-Mail: info@ktg-engelhardt.de www.ktg-engelhardt.de

| Contact | Location | Imprint | AGB's |