Gravimetric dosing technology fitted for your production

Vibratory

conveyor systems series

VF

a manufacturing process must be fed. The conveyor speed can be adjusted continuously to the control unit PG01 via potentiometer or optionally via an external reference signal of 0-20mA or 0-10V

For handling and allocating of bad flowing bulk materials can

dosing belts (VBR) are used instead of dosing channels.

problem materials such as: TiO², chalks, talc, fillers, egg yolk powder, scaly flour, oily nuts, adhesive materials, etc.

Vibration

conveyor VF

41 for

free flowing bulk materials

of all kinds.

conveyer (electromagnetic)

all product touching parts in stainless steel V2a (material no: 1.4301).

control via phase-angle controller

capacity: of 0.5L to 2 m³ / h

Optional:

stocking: round hopper or rectangular hopper

cover for channel

Vibration conveyor VF 41/VBR for bad flowing bulk materials of all kinds

vibrating beltconveyer (electromagnetic)

control via phase-angle controller

Optional:

stocking: round hopper or rectangular hopper

cover for channel

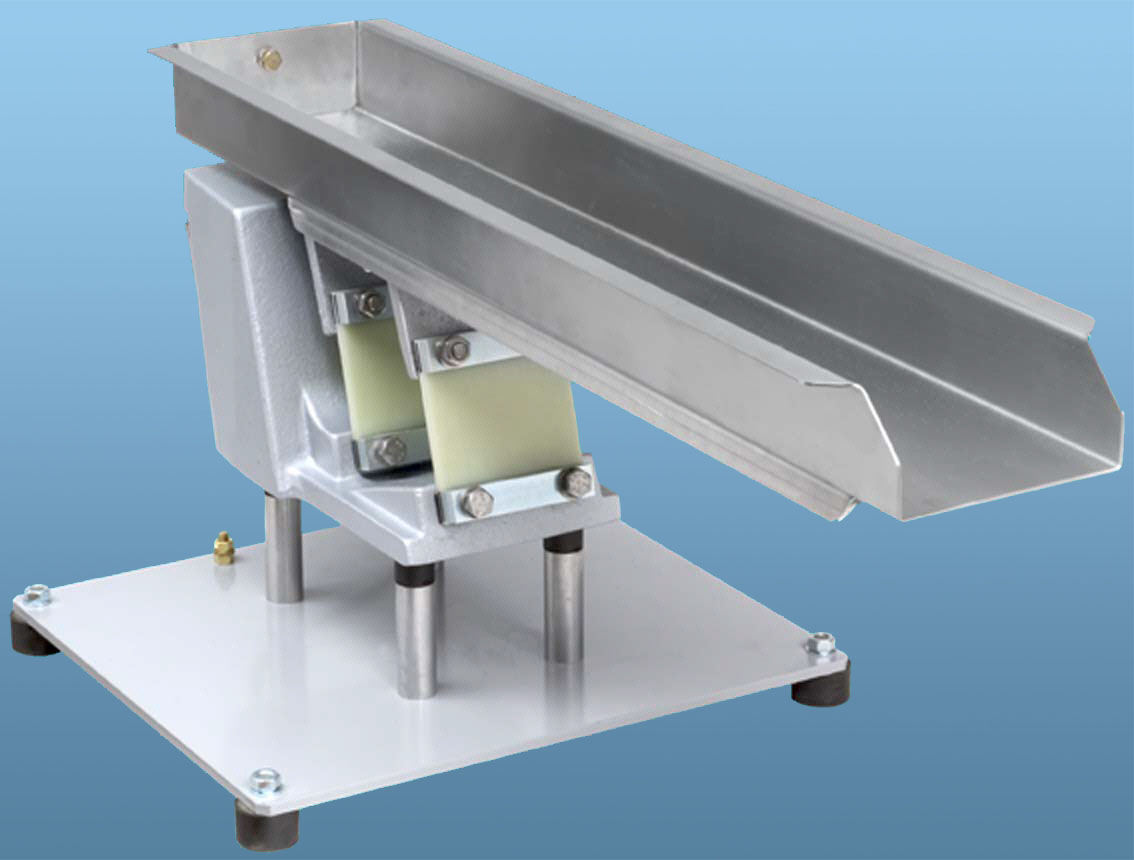

Linear conveyor type VD 0.1

robust aluminum base plate for hopper and vibrator

hopper with appr. 3 litres volume

dosing channel length: 240 mm x width: 40 mm high: 25 mm with vibrator

housing of vibrator in stainless steel V2a / IP 65

product touching parts in stainless steel V2a

overall dimensions of the unit: appr.: l: 270 mm x w: 200mm x h: 420 mm

hopper and dosing channels can also be tailored to customer specifications

throughput here: about 0,1 l/h to 20 l/h (depending on product)

controled via phase-angle controller PG 01

with potentiometer (continuously variable) and stop input

voltage 230V /50 CPS

optional: control 0 - 20 mA or 0 - 10 V

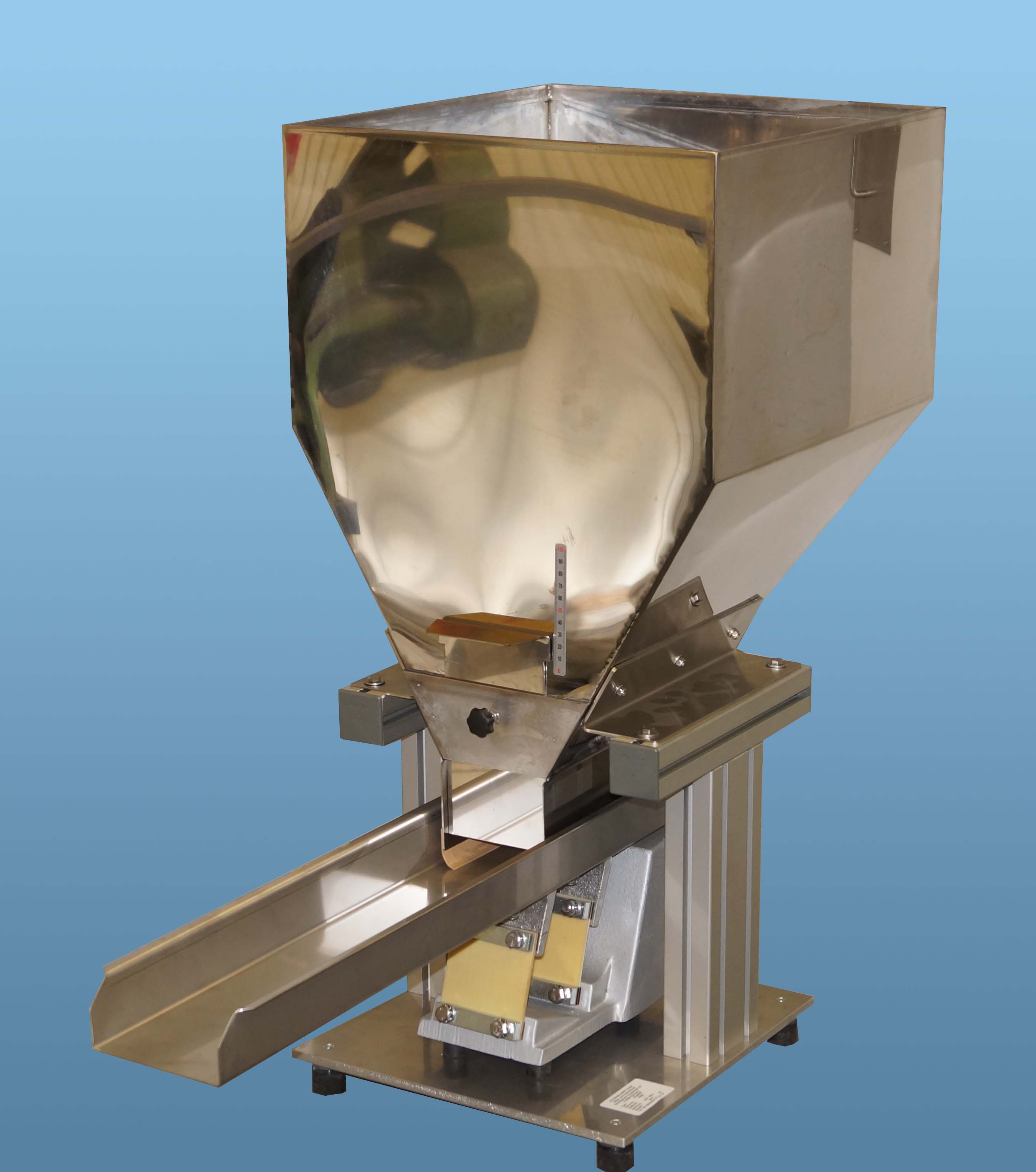

Linear conveyor type VD 40R/60

robust aluminum base plate with vibration dampershopper with appr. 60 litres volume

dosing channel length: 600 mm x width: 120 mm high: 50 mm with vibrator

product touching parts in stainless steel V2a

overall dimensions of the unit: appr.: l: 850 mm x w: 330 mm x h: 820 mm

hopper and dosing channels can also be tailored to customer specifications

throughput here: about 10 l/h to 600 l/h (depending on product)

controled via phase-angle controller PG 01

with potentiometer (continuously variable) and stop input

voltage 230V /50 CPS

optional: control 0 - 20 mA or 0 - 10 V

Vibration

conveyor VF

41 for free flowing

bulk materials of all

kinds.

plant construction here:

frame in stainless steel

vibrating channel with capsuled vibrator,

all product touching parts in stainless steel V2a (material no: 1.4301).

control via phase-angle controller

Telefon: 0911 - 96 44 936 Telefax: 0911 - 96 44 938 E-Mail: info@ktg-engelhardt.de www.ktg-engelhardt.de

| Contact | Location | Imprint | AGB's |